Stainless steel,titanium,ceramics, tungsten, MIM ect,.

Stainless steel parts, watch components, mobile phone parts, jewelry, medical instruments, automobile parts, battery and so on

The coatings can upgrade the cosmetic and prolong the life cycle of the metal parts with coating thickness 0.2~1.5μm.The coating color can be customerized according to customers' requirement. The coatings are wear-resistant and corrosion-resistant and they can pass 48~120hours abrasion and salt spray test.

The DLC coating has low friction coefficient and good scratch-proof with hardness up to 2000HV.The coating can prolong the metal parts life cycle by 2 to 3 times.

Transparent AFP coating can be applied on various surface with 10~200nm thickness and very good effectiveness on anti-finger print.

Environmental Safety

No hazardous chemicals are used or generated in the PVD processes. The coatings can fulfill Rohs, Reach and other legal requirements

Strict control of color deviation

Strict control of color deviation

Programmatic coating processes result in stable PVD colors. The color deviation is strictly controlled by LAB values and color limit samples

Various Colors

Various Colors

8 main color categories with over 60 mass production PVD colors. Customized colors are welcome to meet customers’ demands

High Hardness

High Hardness

The hardness of non-gold coating can reach 1-10x of substrate hardness which prolongs the product life cycle and uplifts product values

Duribility

Duribility

The coatings can pass 48~168H abrasion, artificial sweat and salt spray tests and double product life cycle

Seamless Service

Seamless Service

Company truck service covers Pearl River Delta area, SF Express courier service for outside Guangdong Province. Customer service team over 40 staffs with respond time in 5 minutes can provide 1 on 1 professional service.

Application Scenarios of Vacuum plating processingApplication scenarios of vacuum coating processing

Cellphone

Cellphone

Automobile BPP

Automobile BPP

Jewelry

Jewelry

Watch Parts

Watch Parts

Metal Parts

Metal Parts

Medical Instruments

Medical Instruments

Camera lens, vehicle panel, mobile phone camera, mobile phone tablet, front and rear cover glass of mobile phone, etc.

Mobile phone front and rear cover decorations, camera decorations, mobile phone top decorations, etc.

PC、PMMA

3D Mobile phone injection parts

一、Optical functional film

二、color decorative film

1、AR (Anti-Reflection and Anti-Reflection Coating)----Coating increases the transmittance of the substrate, visible light (400nm-700nm) is about 92% before coating, ≥94% after single-sided coating, and ≥98% after double-sided coating

2 , AF (anti-fingerprint hydrophobic film) - water drop angle after glass coating ≥ 110°, steel wool wear resistance ≥ 100°

3、AR+AF

1、Color decoration of the front and back cover of the mobile phone, any color within the visible light range

Visible light single-sided AR transmittance ≥95%, double-sided plating ≥99%

AF surface pencil hardness ≥9H, steel wool wear-resistant 5000 times, water drop angle ≥100°

Optical Spectroscopy Coating Uniformity≤2%

White optical brightening film (suitable for mobile phones, tablets and other related decorative parts, pure coating, high pressure forming)

Bright metal brightening film (suitable

for mobile phone related decorative parts, coating after offset printing, high pressure forming)

Austenitic is not stainless steel. For example: 316, 304; martensitic stainless steel. For example: 420, 440; precipitation hardened stainless steel. For example: 17-4PH.

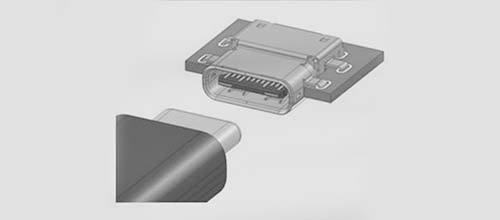

car. For example: turbocharger pins and connecting rods, VOC valve thimbles; 3C industry. For example: Type-C charging head for computers and mobile phones, folding mobile phone gears; clocks. For example: watch cases, bezels and straps; fluid pump valve industry. For example: double tube fittings, needle valve stems; fasteners. For example: lock washers; medical devices. For example: needles.

auto parts

auto parts

watch accessories

watch accessories

3C Parts

3C Parts

fluid machinery

fluid machinery

equipment

equipment

fastener

fastener

The working temperature is 350~480℃, which is 50~100℃ lower than the traditional plasma nitriding temperature. The low temperature process reduces compound formation, helps maintain stainless steel corrosion resistance, reduces product distortion, and saves energy.

Using the auxiliary ion source, the temperature difference in the effective area of the furnace can be controlled within ±5 ℃, and the product performance is more stable.

High-energy ions are obtained by high-frequency pulsed glow discharge, which can effectively remove the passivation film on the surface of the product and improve the hardening efficiency.

Vacuum process, less gas consumption, less pollution, more friendly to the environment.

Technical advantages

Industry advantage

版权所有 © 2021-2039Shenzhen Senfung Vacuum Plating Co.,Ltd. All Rights Reserved.备案号:粤ICP备05103089号  粤公网安备 44031102000667号 百度统计网站地图

粤公网安备 44031102000667号 百度统计网站地图